Focus On

Smartvacuum followed by Smartedge is the perfect combination using the same technique and the same 100% UV acrylic Base coat in both cases. The result is a top-quality end product obtained in a cost-efficient way with a host of benefits including shorter lead times, greater flexibility and increased sustainability.

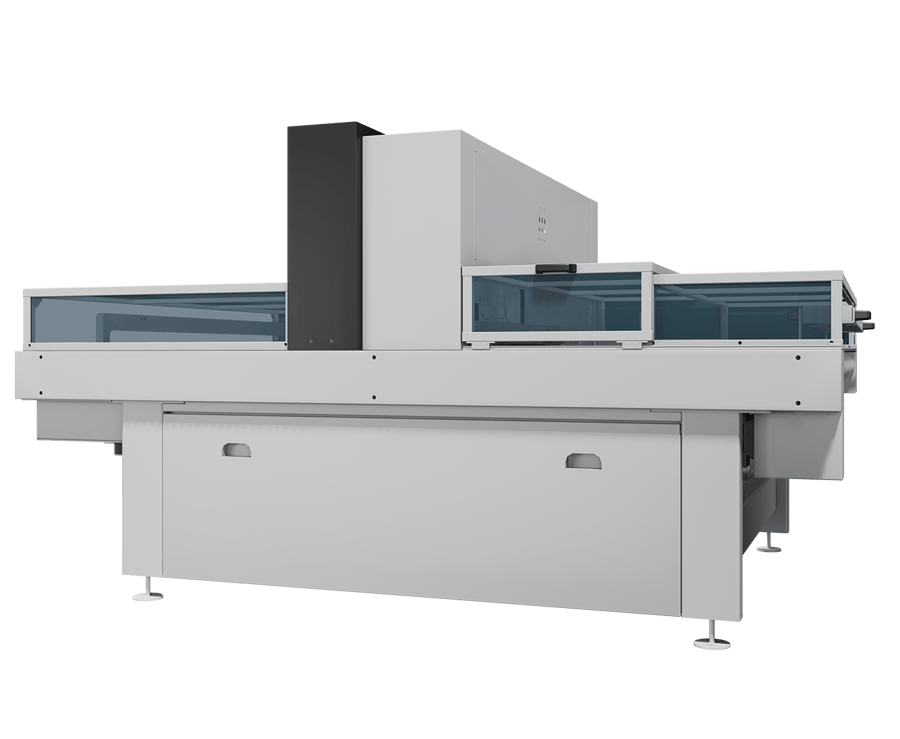

Description

Smartvacuum applies 100/140g per square metre of lacquer in a single pass. Using vacuum technology, the junction between the panel surface and the edge is greatly improved, making it softer to the touch and responding to the trend for slightly rounded edges. Smartvacuum therefore ensures improved quality and reduces the number of operations required to obtain a smooth, matching bond between panel surface and edge, especially when the edge is coated using the same technology by means of our Smartedge solution.Characteristics

- Utilises a solid 100% UV lacquer enabling reduced drying times (3-5 minutes’ flash-off)

- Increased coating stability over time vs. polyurethane or polyester-based products

- Fewer machines to manage, consequently less cleaning required and reduced overall consumption

- Fewer steps and panel handling requirements

- Shorter production lead times

- Lower sanding costs and less waste

- Smaller overall footprint

- Eco-friendly process

Details

Materials

Wood

Fibre Cement