Focus On

Smartsand 2 is equipped with an orbital unit consisting of eight rotating, sliding brushes with adjustable speed. Unlike traditional brushes, this unit is designed to reach all points of furniture doors, including corners and transverse channels.

Description

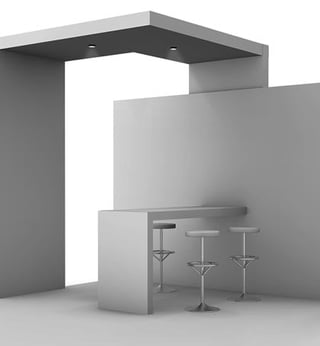

Smartsand is an extremely modular sanding machine. It can be included in coating lines, or used outside the line as a stand-alone machine.

Smartsand, available in two models, is the ideal solution for the smoothing of panel edges and the sanding of any type of panel in wood, wood products and composite materials.

Smartsand, in both configuration 1 and configuration 2, features a quick-release brush unit for easy maintenance and replacement.

On request, the machine can be equipped with multipurpose brushes with two-way rotation, which can simultaneously use two different types of sanding paper, for complex sanding requirements. Smartsand is equipped with a vacuum conveyor belt with rubber feed roller, which ensures maximum adhesion of the panel to the belt surface.

The control panel is equipped with a touch screen for monitoring all operating parameters. The operating speed of the brushes and belt can both be adjusted. The lifting system for the brushes and presser roller frame, which are both independent, allows adjustment of the sanding pressure on the workpiece.

Characteristics

- Extremely modular, for in-line or stand-alone use

- Suitable for sanding any type of panel, flat or shaped

- Quick-release brush units

- All parameters are managed via the touch-screen control monitor

Details

SMARTSAND 1: This Smartsand model is perfect for the smoothing of panel edges and the sanding of panels, flat doors and panels with low reliefs. It features two counter-rotating brushes which can be angled up to 15°.

SMARTSAND 2: Smartsand 2 is suitable for sanding furniture doors and doors with low reliefs, including those of considerable thickness and/or with complex shaping, thanks also to its patented orbital system with eight brushes. Conveyor speed, brush speed and unit lifting are all controlled by separate inverters managed via the touch screen.