Focus On

J-Print MP is a multi-pass digital printing machine, the result of many years of R&D work on digital printing, integrated through the acquisition of JetSet, a company with vast experience in the field of digital machines, supported by Cefla's solid, historic expertise in design and construction of machinery and systems in a wide range of sizes for paint-finishing and decoration of a variety of materials, including wood and wood derivatives, plastic and fibre cement.

Description

J-PRINT MP is a multi-pass flat-bed digital printing machine, equipped with industrial print heads, capable of applying UV-curable inks, widely configurable and designed for both stand-alone use and integration in painting and decoration lines. The complete configuration of the printing module allows output figures of up to 400 m2/h in "draft" mode and 200 m2/h in "quality" mode to be achieved.

J-PRINT MP is widely configurable, both in terms of printing plate size and in terms of colour bar number - up to a maximum of 8 - and number of heads per colour bar - up to a maximum of 8. The graphics management software enables high-definition, multi-colour images to be printed using high-quality print heads.

J-PRINT MP is equipped with UV-LED pinning/drying lamps.

J-PRINT MP uses a special system for ink circulation through the print heads which reduces the required frequency of cleaning. The special shaping of the ink tanks, the continuous stirring system and the automatic management of all critical parameters such as temperature, flow rate and pressure inside the circuit guarantee optimal ink management.

Gray-scale DOD (Drop on Demand) technology, extremely successful in the digital printing market, is a standard technology for J-PRINT MP.

Characteristics

- Perfect for medium-output quality industrial printing

- Available for hard materials

- Printing width 3000 mm

- Different standard lengths from 2500 mm up to 6000 mm

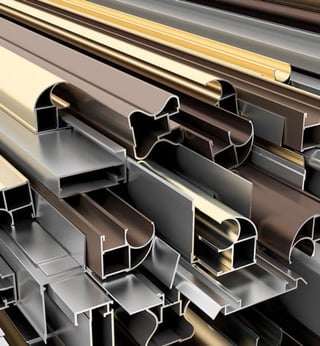

- Perfect for UV inks; compatibility with water-based, solvent and ceramic inks

- Suitable for different types of material, from wood derivatives to plastic, and from fibre cement to metal

- Material conveyor system specifically designed for each different type of product for in-line machine configuration

- Vacuum substrate support surface for stand-alone machine configuration