Video

Focus On

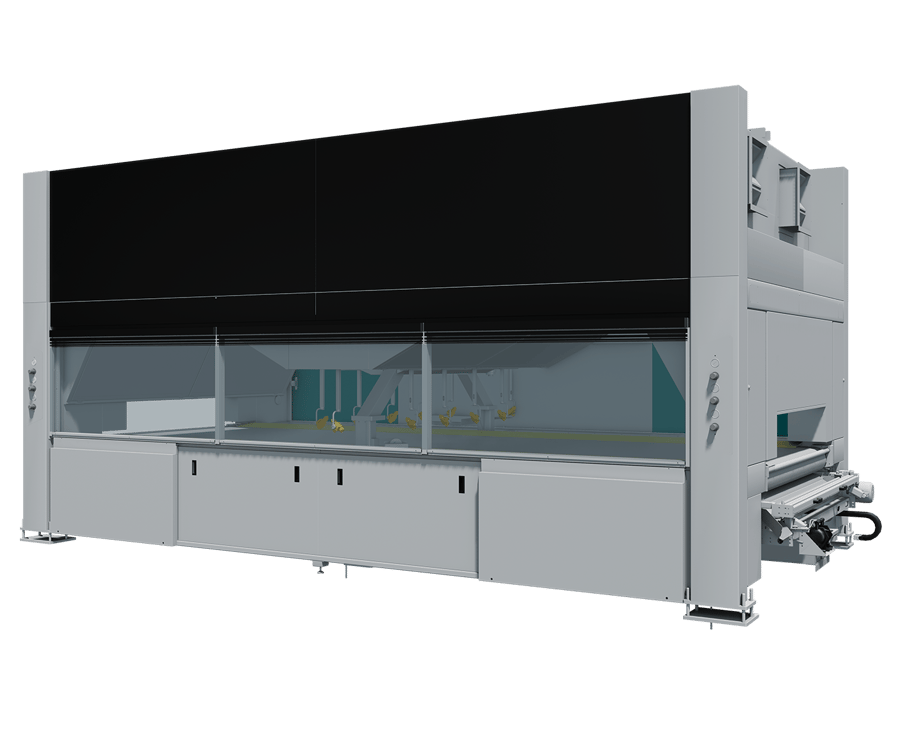

Elispray can manage different work thickness values offering a quick, reliable approach. A centralised lifting system simultaneously positions all the installed guns, ensuring the correct gap between each gun and workpiece. This servo-assisted positioning eliminates the downtime necessary in other manual systems, ensuring production continuity, reliability and quality.

Description

Elispray is suitable for painting at very high speed, without compromising on the coating quality, particularly in terms of efficiency. The guns movement on their elliptical trajectory is achieved through an electric motor, monitored by an encoder, for constant, accurate control of the guns. Elispray can accommodate up to 24 guns split into 2 different product supply circuits.

Characteristics

- High/ultra-high speed processing

- Lower paint consumption

- Finishing quality equal to or superior to oscillating spray machines

- Cleaning operations made easier and less frequent

Details

Elispray is equipped with an automatic gun cleaning system, reducing manual servicing requirements. As a result, machine downtime will be a less frequent occurrence. The procedure can be started on demand or at pre-set intervals according to the work parameters used.

In the variant equipped with water filters, air pushes the overspray to the water curtains. This configuration is particularly suitable for systems that work multiple shifts or create glossy finishes. It must be supplemented with a water clarification Skimmer-type system.

In the variant with dry filters, suction occurs through a large surface with dual-stage dry filters, easy to replace and access for maintenance operations.

Elispray is equipped with a carbon fibre (CFB) conveyor belt system that ensures optimised paint recovery and no overspray on the lower part of the panel.

The CFB conveyor belt complete with recovery carriage is the only system able to ensure recovery of the paint as it was applied, without the addition of solvent. Paint recovery is performed by a counter-rotating roller, while the rest of the system ensures perfect cleaning and thorough drying of the belt. Solvent consumption during work and end-of-session cleaning times are reduced to a minimum.