Article

Glass Painting and Decoration: Technologies, Applications and Advantages for Industry

The painting and decoration of glass are processes capable of transforming a noble material into a truly multisensory experience. There are several methods to achieve this transformation, each with distinct steps and characteristics that endow the glass with specific properties.

Greater resistance, more brilliance, and extensive customisation potential: these are usually the reasons why manufacturers constantly seek to improve their glass painting and decoration processes.

To maximise the outcome, however, it's crucial to consider the numerous available technologies and install production lines capable of delivering optimal finishing in line with customer expectations.

Why invest in glass painting and decoration?

Glass painting and decoration are essential to enhancing manufactured products, improving their appearance, and increasing functionality. While this is a generalisation, it holds true across the various applications enabled by this processing technique, which we’ll explore across different industries.

Investing in equipment and expertise for glass painting and decoration means positioning oneself in the construction and furniture markets with a flexible and resilient proposition. This allows companies to adapt to market trends—offering highly customised solutions—and to seize emerging opportunities from previously untapped industrial sectors.

Industrial applications of glass painting and decoration

Let’s explore today’s main applications of glass painting and decoration, highlighting why leading players in the automotive, construction, and furniture industries choose to treat this material.

Automotive

In the automotive sector, glass finishing and painting play a vital role in both aesthetics and safety.

Glass finishing enhances the vehicle's visual appeal by enabling elegant designs and bold tones. Coatings also offer protection against scratches, UV rays, and environmental contaminants, helping glass parts maintain their appearance over time.

Treated and tinted glass increases passenger comfort by reducing glare and heat while ensuring more privacy and safety. Lightweight glass, combined with innovative finishing techniques, also contributes to reducing vehicle weight, thereby improving fuel efficiency and overall performance.

Construction industry

The construction industry benefits from the versatility of glass for a wide range of architectural solutions—from windows and interior partitions to building facades. But it’s not just about looks: special finishing treatments like low-emissivity coatings significantly improve thermal performance, cutting heating and cooling costs.

Painted glass adapts to architectural designs, while laminated and tempered glass enhances safety by offering better resistance to impacts and breakage—crucial for residential and commercial settings alike. Treated smooth glass surfaces are also easier to clean and maintain, reducing long-term maintenance costs for property owners.

Furniture

In the furniture industry, glass painting and decoration techniques have revolutionised how designers create functional and elegant pieces.

Glass can be shaped, coloured, and finished in various ways to craft unique furniture elements that suit a wide range of styles.

Finishing protects glass from scratches and stains, ensuring durability in high-traffic areas. Treated glass components are also less prone to harbour bacteria and are easier to sanitise—ideal for kitchen use.

Glass painting technologies

There are four main technologies used in glass finishing: spray coating, roller coating, screen printing, and digital printing. Each offers unique advantages for enhancing appearance, functionality, and durability.

INNOVATIVE FINISHING SOLUTIONS

Discover advanced finishing solutions to elevate your business.

Spray coating

Spray coating applies lacquer to glass surfaces using a spray gun on coating equipment in an integrated finishing line.

This method ensures even distribution and a smooth, uniform finish—ideal for decorative glass.

Advantages include fast colour changes, a wide range of finishes, and protective features. Most importantly, it shortens production times compared to manual methods, making it suitable for large volumes.

Roller coating

In this method, paint is applied using rollers in an automated in-line process.

It ensures uniform application, particularly suited for architectural use.

This method also provides an even and controlled paint distribution, resulting in the smooth, uniform finish on the glass that is essential for architectural applications.A key benefit is the automatic edge-cleaning effect, eliminating post-coating cleaning and speeding up the tempering process.

Screen printing

This involves using a stencil (or screen) to apply ink to the glass surface.

Perfect for complex multicolour designs, screen printing suits decorative glass, signage, and artistic pieces, also because it is possible to apply multiple layers of ink, so as to obtain depth and consistency, improving the visual appeal of the finished product.

Screen inks are UV-, chemical-, and abrasion-resistant, ensuring durability and colour retention. It’s also highly versatile, applicable to various glass types—tempered, laminated, and more—making it ideal for automotive, architectural, and consumer sectors.

Digital printing

Inkjet technology prints high-resolution graphics directly on the glass.

Ideal for customised and intricate designs, it accommodates diverse patterns, colours, and dimensions, supporting tailored projects.

This technique minimises waste (no stencils or screens needed) and shortens lead times due to rapid set-up.

Glass finishing techniques

In addition to painting, finishing techniques enhance glass’s functionality and safety. The three most common are etching, sandblasting, and film application.

Etching

Etching removes a thin surface layer to create patterns or designs—mechanically, chemically, or via laser for precision.

Sandblasting

Uses abrasives applied at high speeds to texture or smooth glass surfaces, creating uniform finishes or decorative effects.

Film application

Applies a thin vinyl or polymer film to glass for aesthetic or protective purposes.

Protective films enhance resistance to scratches and chemicals, improve energy efficiency, or increase privacy in buildings and vehicles.

Today, special paints can be applied by spray coaters or roller coaters and, once properly dried, form a film directly on the glass—streamlining the process and ensuring high-quality results.

Cefla Finishing solutions for glass painting and decoration

Cefla Finishing has identified key challenges faced by glass manufacturers and, through partnerships with global industry leaders, developed a portfolio of technologies that ensure:

- high and uniform application quality

- transfer efficiency

- ease of use

The range includes roller and spray coating machines, as well as drying solutions.

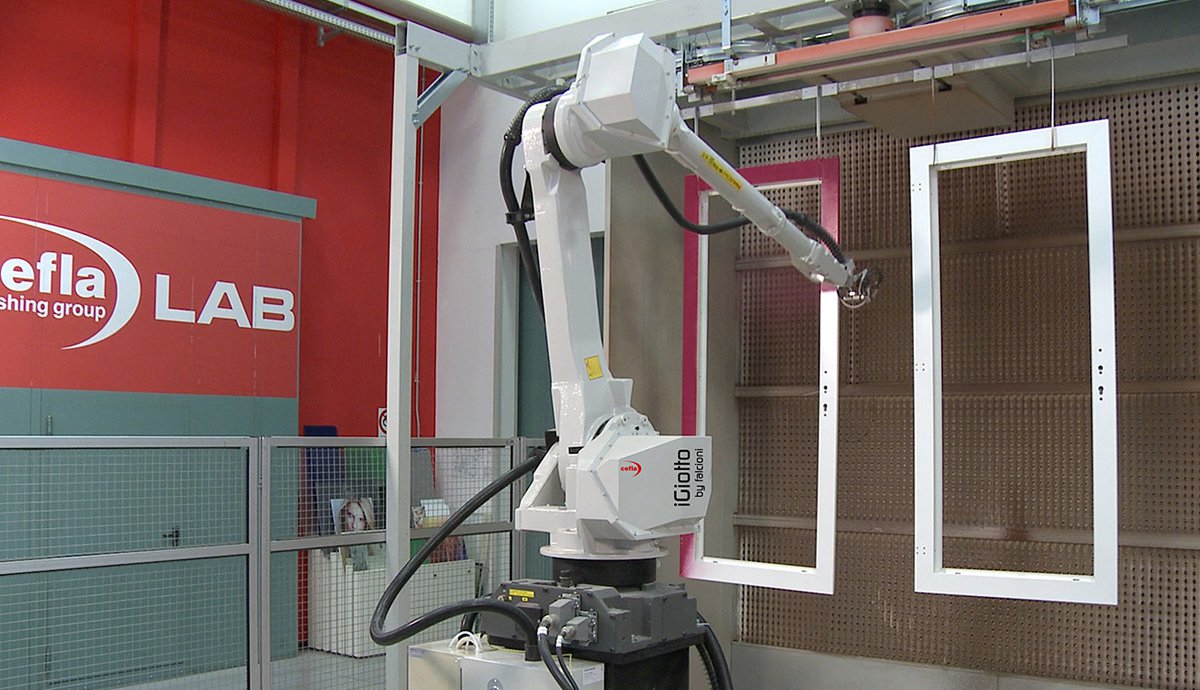

Cefla Finishing machines feature patented technologies and are engineered for ease of use. The main goal is to maximise efficiency by enabling operators, even those without specialised training, to quickly master the controls and procedures. Cefla Finishing also develops automated lines that cut down on expenses and enhance coating uniformity, which contributes to managing consumption and its associated costs.

Technologies:

- Framecoater: Coats up to four perimetric sections of a glass sheet, thereby appearing as a frame. Avoids the need for manual coating.

- Multicoater: Patented roller coating technology with remarkable application capacity allowing high coverage and uniformity.

- Glasscoater: Easy-to-use roller coating machine suitable for ceramic glazes and organic products. Maximum reliability and application uniformity.

- Prima Glass: The ready-to-go spray solution to automate your glass decoration process. Extreme flexibility in colour changes.

- Mito Glass: Reciprocating spray coating machine, easy to use and fit for frequent colour changeovers. Patented plenum accentuates transfer efficiency.

- Glassoven: Ovens with a consolidate design, made to optimise air circulation and drying efficiency.

- Glasscool: Cooling tunnel with high-speed air blade ventilation on both sides of glass sheet.

- Solarcoater: Patented roller coating technology applying anti-reflective coating with over 100 machines installed worldwide.

Looking for the ideal solution for your glass painting line?