Who knows a company that won’t want to cut costs wherever possible, saving money directly from lower consumption and indirectly by saving time on repetitive procedures?

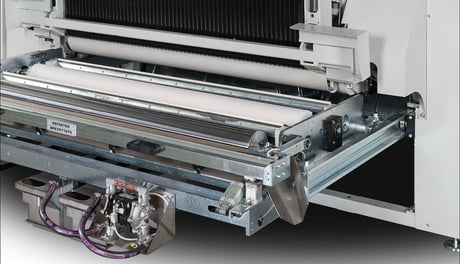

A patented paint recovery system which cleans your equipment reduces the amount of paint wasted and also the quantity of detergent needed to clean. It also saves time when changing from one production run to the next when colour changeovers are involved.

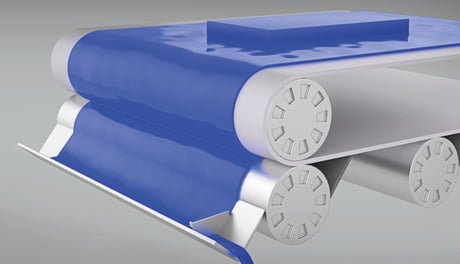

A wider belt under the painting surface collects excess paint during spraying, thereby protecting the machine's filters. A counter-rotating roller also recovers paint while the machine is working, so no downtime is necessary. Better belt condition leads to longer belt life and fewer stoppages to replace them.

The amount of detergent needed is reduced to a minimum. Less than 50 litres of detergent per shift are required on average to perform cleaning operations.

Take a look at this short video to see how the system works and contact us if you desire more detailed information. Our spray coating machines can be equipped with this device.