Once a company moves from manual spraying to automation, many workpieces will require the operator to program the spraying software carefully, so that coating is performed correctly, consistently, and without leaving uncoated surfaces or using excessive quantities of paint.

The more complex the geometry, the more complicated the programming phase will be, requiring hours or even days of trial and error stages and fine-tuning of the movements that will ensure a quality finish. If you have ever faced this issue, be aware that a spraying robot that programs itself allows you to save all the programming time and effort, delivering the results you want and improving your production capacity.

The reason for a robot and the decisions you need to make.

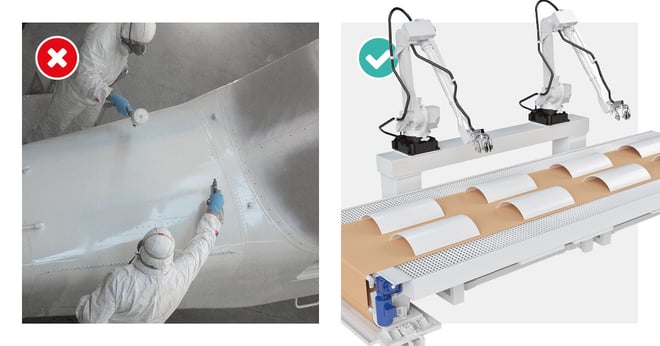

A spraying robot has a huge advantage over a human operator: it never gets tired or sick and always sprays the same way, from the start to the end of a shift. However, you need an expert to instruct the robot and program it for each new production run.

Most people will accept this as a fact, but it is not entirely true. With our spraying robots, it’s your decision: teach the robot or make it learn on its own.

Would you like to enhance your production with smart automation?

Download our report now and discover how to achieve consistent quality and efficiency in your company.

Self-programming capabilities save everyone’s time and your money.

An expert will spend hours determining the single movements that a robot needs to accomplish in a precise sequence. When developing our equipment and software, we knew how important it was to create a solution in which the robot was able to learn and teach itself. This involved 3D reading barriers, optimisation of trajectories, speeds, quantities, opening and closing of spray nozzles etc. To summarise what our robots do: they process data and translate it into immediate action, and may conserve this knowledge forever.

Flexibility is not a challenge for these robots.

Cartesian spraying robots and anthropomorphic spraying robots fitted with 2D and 3D reading barriers and the appropriate software will allow for flexible production, increasing your efficiency, the quality of the product and time to market; especially where small volumes and huge variety are requested.

Moreover, this degree of intelligent automation enhances your company’s sustainability.

LOOKING FOR THE IDEAL COATING LINE SOLUTION?