Certain products are still coated manually because of their inconvenient shapes or because they won’t fit easily onto a standard line. Or simply because they have always been coated manually, so the manufacturer never thinks to search for an alternative solution.

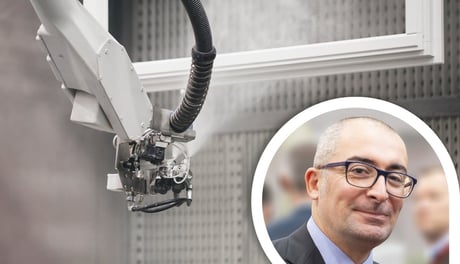

That’s why we are proactive when faced by a request to increase productivity, limit the amount of handling operations made by the operator and improve coating consistency. Our solutions especially through automation as the logical evolution to manual spray coating.

Table legs, stairs, unassembled chairs and loudspeakers

Some products are sprayed manually, moved manually to drying booths and spend more time than necessary in production before reaching the market. Not only is time an issue, but also the physical effort needed to sustain the manual process.

Automation provides an answer by speeding up the process, ensuring quality is consistent and allowing qualified staff to dedicate time to more important tasks.

An overhead line built to handle such pieces can deal with several units at a time, 10 or 20 fixed to a transporting bar. A reciprocating overhead spray coater fitted with a whirling cup device for electrostatic atomisation ensures excellent coating quality, above all consistent, piece after piece. This reduces handling operations and maximises productivity. Automatic rotation of the pieces speeds up the coating stage, optimised by the enveloping effect of the atomised spray, which also significantly reduces lacquer consumption and saves related costs.

Pieces will then be transferred automatically to a drying oven using controlled hot air ventilation for the precise time needed to complete the surface enhancement process.

Each product deserves a personalised approach

Not every product is the same. Our approach will examine the variables in the product (shape, weight, substrate) and take into consideration your targets (budget, productivity, quality). The resulting line concept, moving you from a manual process to automation, will also be designed to ensure maximum sustainability, based on standard technologies and customised to your specific needs.

Contact us and discuss your needs with a finishing expert.