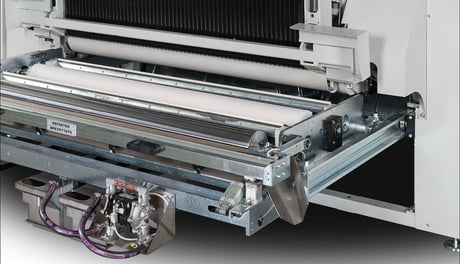

Today, we focus on spraying machine paint recovery and cleaning system.

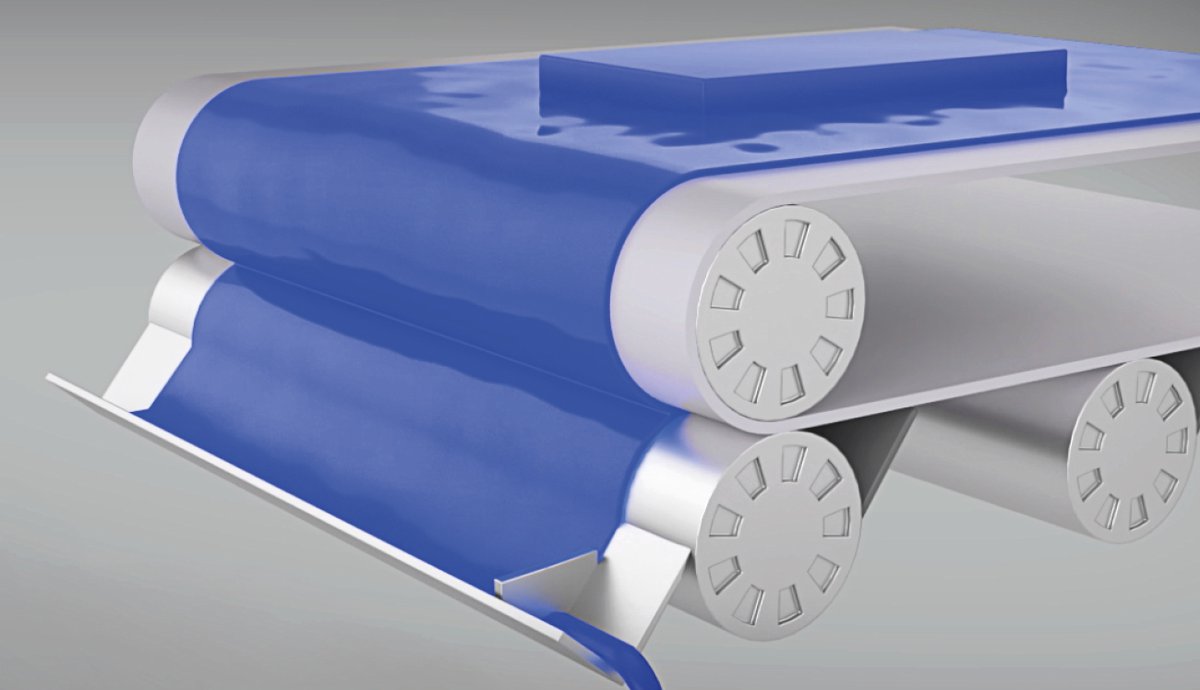

Less detergent means lower operating costs, it safeguards your equipment and ensures a healthier environment.

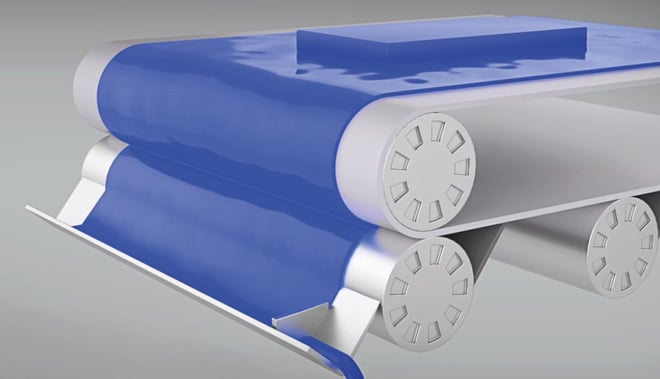

Working with a sprayer or a robot with a belt that allows paint recovery means cleaning the belt regularly to remove any trace of the applied product. If your spray cleaning system is conventional, you will not only throw away a lot of paint, but you will also use a significant amount of detergent. Conventional systems also lead to rapid belt deterioration, either through the abrasion from belt cleaner blades or aggressive solvents. You will benefit from:

- increased paint recovery

- detergent consumption which drops to around 50 litres per shift

- fewer production stoppages to replace belts

- minimal end-of-session cleaning times

- enhanced production efficiency

Our simplified patented system allows you to reduce machine recovery times and detergent costs, even when changing colour.