What is spray coating?

Spray coating is one of the most commonly used surface finishing techniques. Spraying can be done manually or automatically, using spray coaters which can also be very different from each other. For example, Cefla Finishing spray coaters include simple or complex lines, flatbed lines, elliptical solutions with vertical lines, as well as high-tech spray coating robots, all relying on software to ensure top class performance.

features

How to choose the best spray coating technologies?

There's a huge variety of products that are finished by spray coating. For all of them, the requirements are the same in an industrial finishing line. In other words, whether in the automotive sector, the furniture sector, or for any durable consumer goods, the factors that determine the choice of spray coating machines are:

- Guarantee of superior and consistent quality finishes, for which line and process automation is essential.

- Flexibility in every phase of the process: possibility of processing small batches efficiently, with customizations and special processes on request.

- Transfer efficiency and productivity: essential for securing good margins. Software and IoT solutions help monitor and optimize processes through every stage, while patented technologies help to become more productive.

- Constant innovation: to define better performing and increasingly effective methods, and to develop new techniques for high-performance surfaces.

Some spray coating application areas and finished products

APPLICATIONS

Plastic components

Thermal-acoustic insulation in wood-cement

Acoustic foam panels

Bedrooms

Types of spray coating machines

Spraying booths, and in particular, pressurized ones, guarantee top quality and excellent results thanks to the absence of atomised powders and particulate matter, while maintaining a constant temperature and air flow internally. The manual spray booths made by Cefla, either dry or wet, are ideal for primary manufacturing companies relying on the irreplaceable manual skills of professional skilled labour.

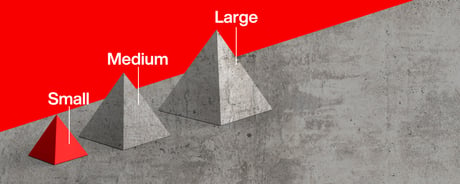

Our oscillating spray coaters, with one or two arms, meet the needs of manufacturers who process small-, medium- and also large-sized production volumes. Our range of oscillating spray coaters integrates the latest technological innovations developed for different industries.

Each solution can be customized according to the degree of production efficiency and flexibility needed, and in such a way as to make service easier. Different materials, flat and textured panels, special software, reading barriers. The machines included in this category are Prima, Mito, Easy and Roctre.

The perfect rotary or elliptical spray coaters for users looking for unrivalled performance in terms of productivity and speed, without ever compromising on quality. The high number of guns in these spray coaters allows for uniformity of application. The machines in this category are Rotostain and Elispray.

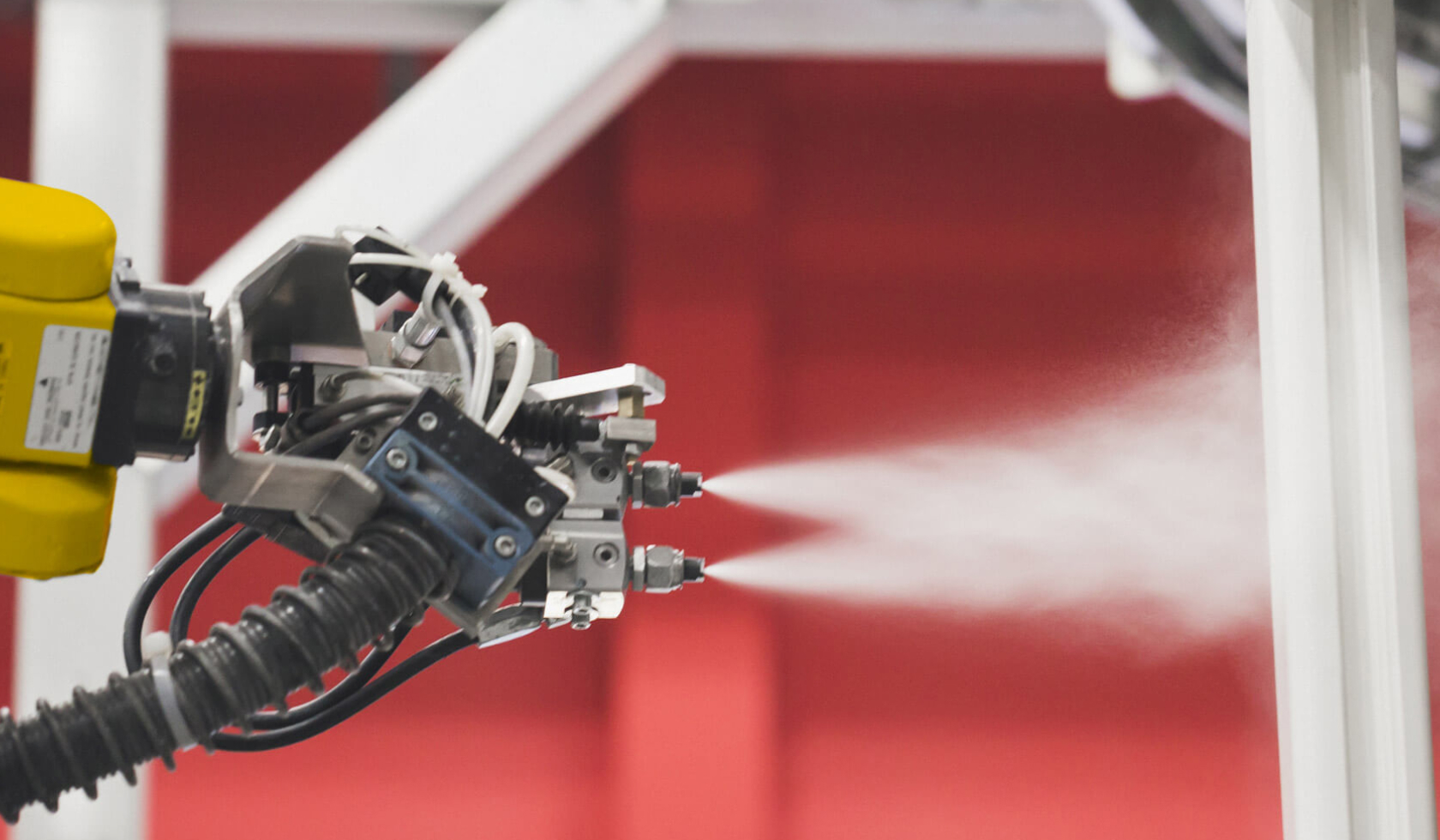

The spraying robots feature high production capacities for a top rate quality finish. Our range of Cartesian robots working horizontally ensure flexibility and speed and the same time, computerized precision, even in oscillating mode with moving workloads. Our anthropomorphic coating robot igiottoApp, with 6 axes, combines the best painting technologies with maximum versatility in handling three-dimensional objects. Configurations with one or two robots operating in stationary load or oscillating mode are possible. In tracking mode, with two robots processing the same workpiece simultaneously, processing times drop dramatically. The machines in this category are iBotic and iGiotto App

Focus On

iGiottoApp and cVision

When it comes to coating complex three-dimensional objects, achieving top quality finishing while maximising production efficiency and minimising machine downtime is quite a tall order. iGiottoApp and cVision can respond to this need. This automatic coating system includes a latest generation 3D reading feature (laser + video camera) to capture the positions, dimensions and shapes of the workpieces fed along the line, to a degree of precision never achieved before. cVision acquires the 3D image of the piece to be coated and uses its special software to determine the best trajectories.

Discover more

Some of the machines for spray coating to make the most of your finishing line

Products

Case studies

Projects

WHITEPAPER

Do you know how much it costs you to work with a paint recovery system?

Learn More

MAGAZINE

Why choose a Cefla Finishing automatic spray coating solution?

Whatever your need, we will find together the optimal solution for you.

Would you like to have more information?

Connect

Frequently Asked Questions

Frequently Asked Questions

- That the coating must match the substrate material to ensure proper adhesion.

- That the piece being coated must be able to pass through the machines/systems.

- Those who opt for a paper conveyor machine will observe many similarities with manual coating methods: start-up, spray gun feeding, cleaning and replacing filters.

- Those who go for a machine with continuous belt conveying will need to perform preparation and maintenance associated with the retrieval and cleaning trolley; nevertheless, these tasks are simple.

- On machines with paper conveying and paper filters, very little time is needed. All you need to do is clean the guns and pump, and replace and discard filters as necessary.

- Continuous belt machines require more time at the end of the shift as maintenance tasks concerning the belt retrieval and cleaning device needed to be performed.

In the case of a machine with continuous belt conveying, cleaning and retrieval system maintenance is also required.

Machines with water filtration will also require maintenance of the continuous filtration device.