Entirely free from size constraints

OMNIDRY, the final frontier in vertical drying oven design, provides the revolutionary capability for fully automatic management of piece height, while retaining all the outstanding characteristics of a standard Cefla vertical oven. It can carry out all three stages (flash off, drying and cooling), even for coatings that need longer drying times, while minimising the use of floor space. The number of trays can be varied from 16 to 168.

Flexibility and productivity

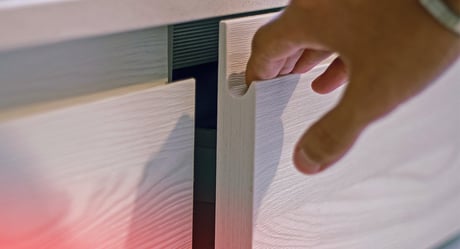

FLEXPRO (patented), is the revolutionary feature of the new vertical drying oven Omnidry, which allows you to manage the loading thickness completely automatically. It represents the perfect compromise between productivity and flexibility. Thanks to FLEXPRO, the system recognizes inbound objects, independently adjusting the load height. The oven handles the entire cycle without operator intervention and never stops the production. This innovative solution is perfect for robotic applications that allow the finishing of pieces with different sizes.

Cefla’s expertise enables us to take another major step forward: the new generation of

Omnidry vertical drying ovens provides automatic management of piece variation.

Flexible system layout

Belt or rack trays can be incorporated facilitating the handling of workpieces entering and exiting the oven: a roller conveyor combined with rack trays or a belt conveyor using motor-driven belt trays.

Horizontal upgrade

Extreme modularity: Omnidry can be expanded with an additional 2 or 4 sections according to the actual production volumes or those envisaged if an increase in productivity is required or an increase of the drying time.