Wuxi Rayard: automation and integrated solutions to improve sustainability

Project Details

Customer:

Wuxi Rayard

Country:

China

Media Video:

Who’s the customer?

Founded in 1993 in the city of Taizhou, Wuxi Rayard Wood Industry specialises in the production of doors, drawer sides and decorative raised panels. With a factory of almost 200,000 square metres and a team of over 1,200 employees, the company is one of Ikea's key partners: its annual sales touch almost 170 million dollars.

The challenge

Wuxi Rayard sees sustainability as a great growth opportunity. Increasingly environment-aware consumers prefer furniture that’s sustainable, so those able to meet their wishes naturally gain a competitive edge. Since finishing lines play a pivotal role in Wuxi Rayard's production process, the company needed a technological partner to help renew its machinery pool with solutions that reduce coating and solvent use and, more generally, consumption.

The Cefla Finishing solution

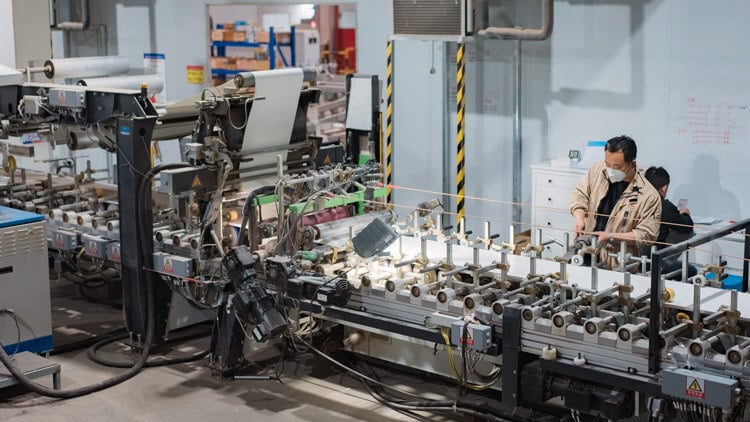

The Wuxi Rayard plant is divided into different areas: each workshop performs specific tasks with specialised workers and machines: from material preparation and woodworking to finishing and packaging.

To boost sustainability, Cefla Finishing has installed two complete lines, implementing a series of integrated sanding, coating, drying and wrapping processes.

Results

Thanks to the lines developed by Cefla Finishing together with Wuxi Rayard, even the delicate finishing stage has now been fully integrated into the automated production process; this optimises the entire value chain and, above all, drastically reduces consumption of lacquers and solvents. Heightened plant performance will allow Wuxi Rayard to position itself on the market as a provider attentive to the environment.

The right balance of quality, efficiency and sustainability

As a supplier to Ikea, Wuxi Rayard's top priority is to maintain a combination of high quality, cost control and manufacturing efficiency. That’s why, right from the very start, the group's production systems have been fully automated.

Over the years, this approach has yielded several tangible advantages: lower operating costs, fewer workers to achieve smooth execution of tasks, greater efficiency, optimised processes and increasingly higher quality standards. By drawing on Cefla Finishing's expertise, the company now aims to achieve excellent sustainability-related KPIs at a stage of the production cycle that can have considerable environmental impact: finishing.

The lines implemented by Cefla

Working side by side with Wuxi Rayard technicians, Cefla’s experts set up two lines, developing a series of tailor-made, ultra-high-efficiency solutions that can be integrated with existing systems.

For example, furniture is now coated using a spray system, controlled by the high-speed Roctre machine. The products are then placed inside Omnidry, a vertical oven that manages variously sized pieces and automatically self-adjusts without any need for worker intervention; lastly, they undergo a final polymerization-type drying process via the plug-and-play UV-R solution.

The other automated line implemented by Cefla is dedicated to product wrapping, and uses systems provided by Düspohl, the Cefla brand that specialises in this machine type.

A long-standing, innovation-driven partnership

Over the years, the relationship between Wuxi Rayard and Cefla Finishing has, thanks to their shared spirit of innovation, gone from strength to strength. This strategic cooperation is much more than a traditional customer-supplier relationship. For example, the Chinese group actively participates in Cefla's exhibitions and Open House events, personally experimenting the latest technologies and solutions to meet the industry’s specific needs.

Cefla Finishing: experience and professionalism for Wuxi Rayard

Wuxi Rayard prizes Cefla Finishing's experience, cutting-edge products and comprehensive technical support. “The excellent stability of Cefla lines helps us increase margins while ensuring production quality”, said a company spokesperson. “Through the many years of our partnership we’ve constantly enjoyed outstanding performance, great professionalism and services that match the product, confirming their leadership in the finishing sector”.

“Cefla Finishing has helped us improve our cooperation with Ikea and other supply chain partners. That's why we enthusiastically recommend them”.