WIP Industries goes for automation and boosts productivity

Project Details

Customer:

WIP Industries

Country:

Romania

Media Video:

Who’s the customer?

Founded in 2013, WIP Industries Romania is part of the WIP Group, a Swedish business based in Åseda. Right from the start, WIP Industries has worked in close collaboration with its sibling subsidiaries, making and finishing cabinet drawers. These drawers are subsequently used to create various furnishing accessories such as bedside tables and chests of drawers. At present, the company employs 230 people working in two factories with a combined floorspace of 35,000 square metres.

The challenge

Following a surge in demand, WIP Industries needed to install automated spray and roller coating lines in a new factory. But there was a problem: the company had no experience with automation and literally had to start from scratch. A partner was therefore needed: one who could not only deliver reliable high-performance technology but also provide close support to ensure proper implementation of the purchased solutions.

The Cefla Finishing solution

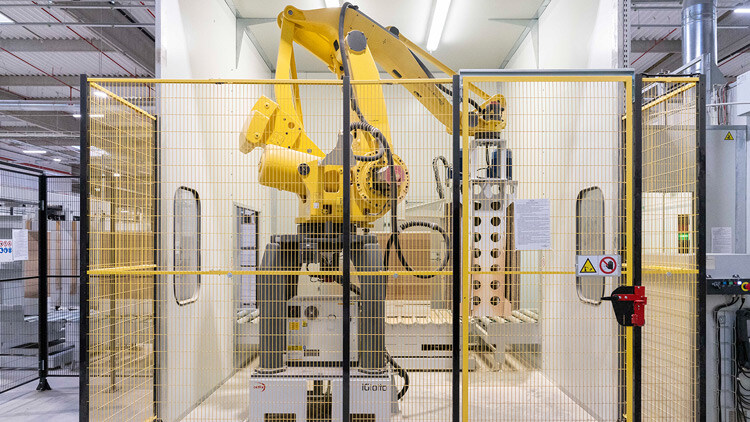

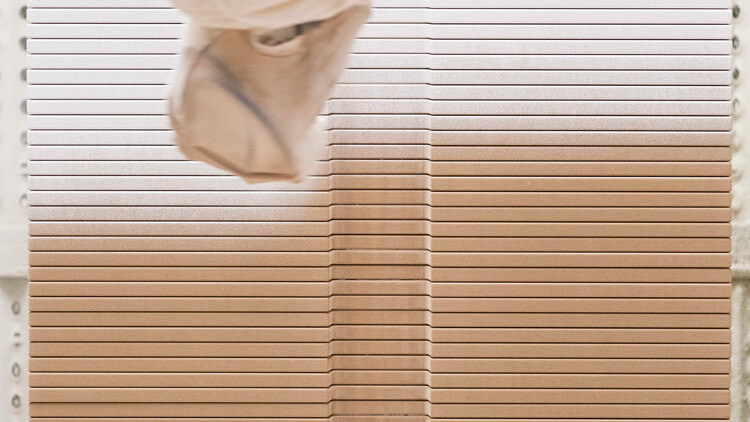

Cefla Finishing supplied WIP Industries with iGiotto articulated robots to enable fully automatic ‘stacked edge’ coating. At the same time, a series of Smartcoater PRO roller coating machines were installed: these can process items of different shape and thickness, as well as panels with varying degrees of deformation. All, of course, with a focus on simplicity and efficiency; operating parameter settings needed to be easily accessible and allow immediate savings in terms of time and materials while improving coating quality.

Results

Thanks to the partnership with Cefla Finishing, WIP Industries soon succeeded in starting up the lines in the new factory. What’s more, they also built up the know-how needed to organise production, allowing them to make the most of a technology that, until then, they’d never used.

More specifically, the installed machines allow for optimal edge coating, helping WIP Industries improve the appearance of their products, provide personalised finishes and ensure better durability and waterproofing.

WIP Industries goes for automation and boosts productivity

At present, WIP Industries can count on fully automated production lines supervised by specialised workers. Overall, the facilities produce, process and package approximately 8 million sets (24 million pieces) per year.

“These lines cut, wrap and process the items. Finished parts are shipped to intermediaries or are packaged directly for delivery to end customers,” explains Mats Holmgren, General Manager of WIP Industries Romania. He also points out how things changed drastically in 2023, when the company signed an agreement for the production of lacquered furniture. “Since this was a multi-year contract, we needed to build a new specially-made factory, with a surface area ofapproximately 22,000 m2”.

Starting from scratch... and ending up in pole position

WIP Industries therefore needed to acquire latest-generation machines to complement or completely replace manual processes with automatic spray and roller coating systems. “We therefore turned to Cefla Finishing, who helped us install two specialised lines, thanks to which we have significantly increased the quantity and, above all, the quality of the products we make,” points out Holmgren.

The first line spray-coats the edges of the stacked panels: thanks also to integration with an automatic sanding system and special areas for inspection and manual finishing, this allows all sides of a stack of panels to be sanded, coated and dried every 150 seconds. The second roller line adapts the coating processes to the needs of the plant perfectly, including the way shifts need to be organised. Holmgren defines this solution as ‘state-of-the-art’ and adds that it will “give us peace of mind for many years to come.”

The added value of Cefla Finishing solutions

To maximise flexibility, the roller line supplied by Cefla Finishing consists of a succession of applicator machines, sanders and UV ovens. This architecture has the advantage of allowing line customisation according to specific requirements. That, in turn, ensures maximum flexibility, essential in third-party finishing set-ups (as with WIP Industries) that that need to transition from one colour or thickness to another without lengthy downtimes. Furthermore, the coating line incorporates a roller printing machine to create wood effects etc. starting with a base colour that’s prepared using the previous machines incorporated on the line.

Efficiency, user-friendliness, accessibility and control are, top priorities for this Romanian company, which succeeded in configuring the machines even though their workers were inexperienced. Easy access to the equipment allowed the initially unqualified staff to perform maintenance and cleaning tasks quickly.

Moreover, control of the coating process has been simplified (allowing assessment of both coating consumption and quality of workmanship), making it extremely fast, allowing any parameter adjustments to be made in the shortest time possible.

More than a technology supply agreement: the value of a communication-based partnership

Holmgren underlines the importance of the partnership with Cefla Finishing. Despite the geographical distance, Cefla consultants have always communicated effectively, allowing WIP Industries to get the best from the installed machines. Even without any prior experience with such solutions, the relationship has gradually gone from strength to strength, allowing the company to master innovative spray and roller coating techniques.

Thanks to Cefla Finishing, WIP Industries now has a clear understanding of the potential of automation technologies. Holmgren concludes by recommending Cefla machines: "I most certainly recommend their machines: they’re extremely reliable and also suitable for those who need, as we did, to enact major changes without having the experience to understand how to go about doing so."

"The relationship with Cefla Finishing has steadily evolved to allow us - who had no experience in automatic spray or roller coating techniques - to discover and use all the potential of latest-generation finishing solutions"

Mats Holmgren, General Manager of WIP Industries Romania

Products